Shell and Tube Heat Exchanger

Silicon Carbide

Heat Exchanger

The silicon carbide heat exchanger is a new-generation heat exchanger that uses silicon carbide material as the primary heat transfer medium, offering excellent thermal conductivity, corrosion resistance, and high-temperature stability.

Applications

- Pharmaceuticals

- Fine Chemicals

- Chemical Engineering

- Metallurgical Industry

Silicon carbide heat exchangers are an ideal solution for harsh and corrosive operating conditions.

Applicable Media

- Large Surface Area

- High Efficiency

- Compact Design

- Strong Adaptability

- Energy Efficient

- Halogenated Compounds

- Salt Solutions

- Organic Compounds

Engineered for Superior Performance

We offer silicon carbide heat exchangers for demanding industrial applications.

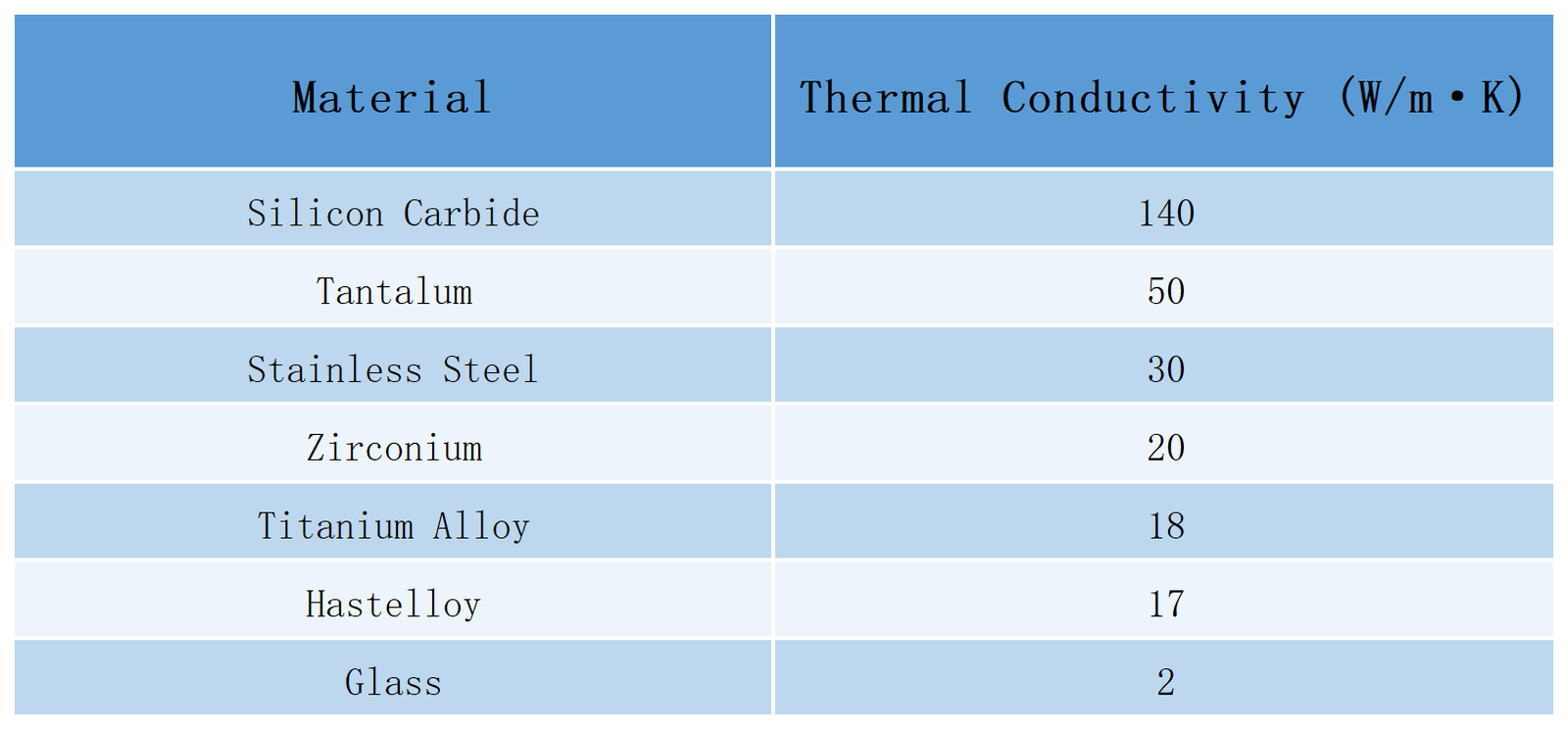

High Thermal Conductivity

Silicon carbide offers thermal conductivity significantly higher than conventional materials.

Under the same heat transfer duty, it enables a more compact heat exchanger design, reducing overall equipment size.

Under the same heat transfer duty, it enables a more compact heat exchanger design, reducing overall equipment size.

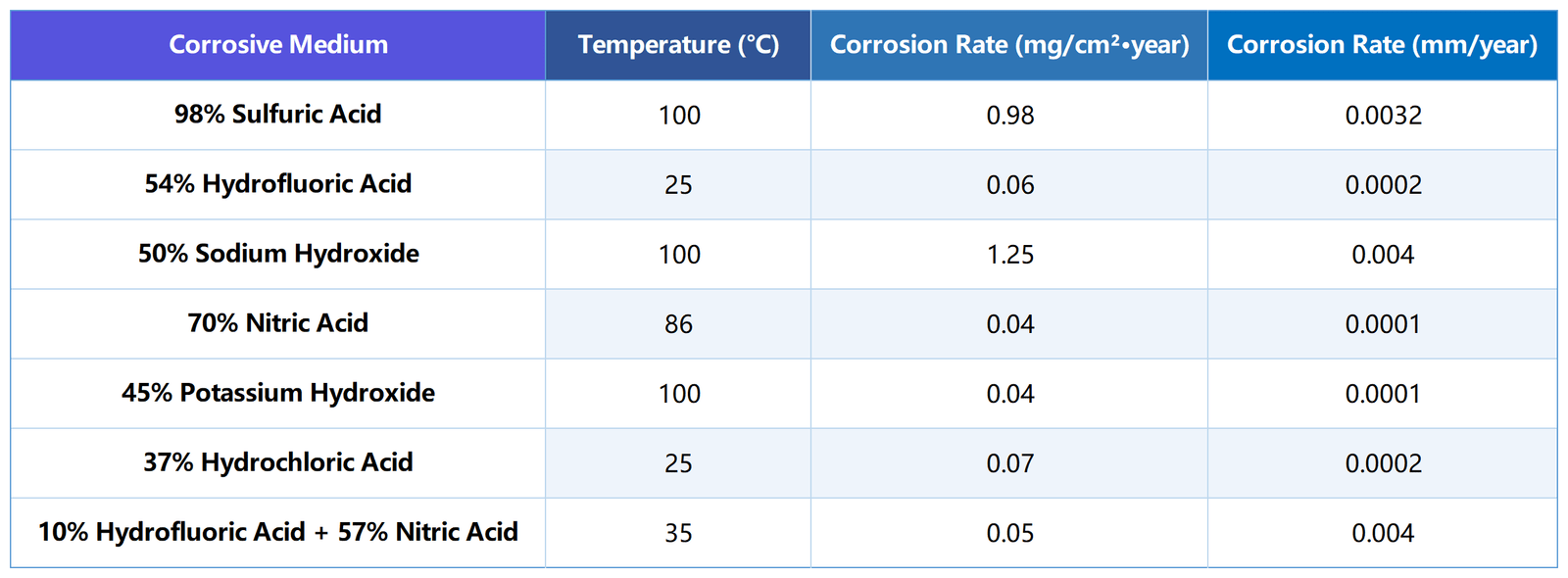

Excellent Corrosion Resistance

Outstanding resistance to corrosion, oxidation, and erosion.

Capable of long-term operation in high-concentration sulfuric acid, nitric acid, phosphoric acid, mixed acids, strong alkalis, and oxidizing media, ensuring an extended service life.

Capable of long-term operation in high-concentration sulfuric acid, nitric acid, phosphoric acid, mixed acids, strong alkalis, and oxidizing media, ensuring an extended service life.

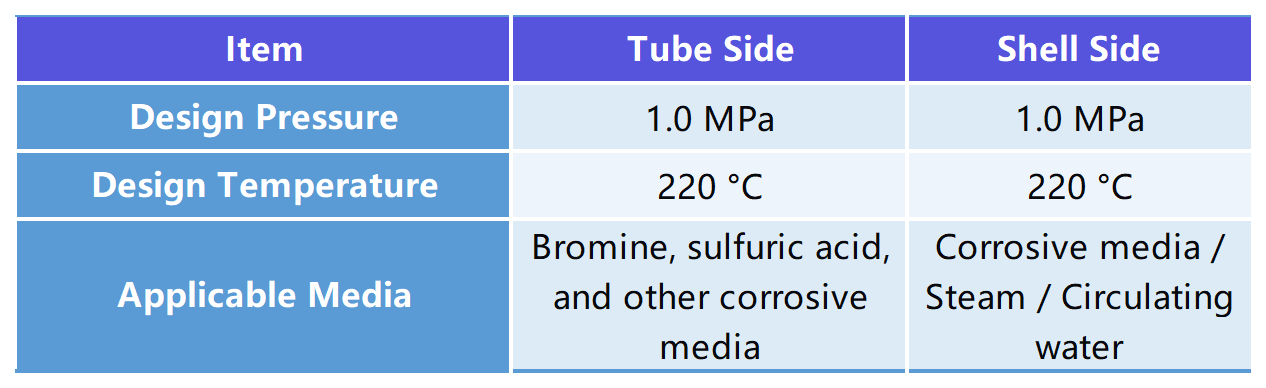

High Pressure, High Temperature

& Wear Resistance

Exhibits excellent performance under high pressure, high temperature, and abrasive conditions, suitable for demanding industrial processes.

Long Service Life & Easy Maintenance

Designed for long-term operation.

Individual tubes can be independently replaced, making inspection and maintenance convenient and cost-effective.

Individual tubes can be independently replaced, making inspection and maintenance convenient and cost-effective.

Flexible Media Handling & Reliable Sealing

Both tube side and shell side can handle corrosive media, allowing flexible interchange of different process fluids.

The advanced double tube-sheet sealing design, combined with high-performance sealing materials, effectively eliminates leakage risks.

Tube sheet lining: PFA / PTFE

Shell lining: Fluoropolymer or Enamel (Glass-Lined)

The advanced double tube-sheet sealing design, combined with high-performance sealing materials, effectively eliminates leakage risks.

Tube sheet lining: PFA / PTFE

Shell lining: Fluoropolymer or Enamel (Glass-Lined)

Contact Us

Address

The intersection of Haihua Street and Dahai Road, Weifang Binhai Economic Development Zone, Shandong Province

info@tershion.com

Phone

+86 176 6362 2159